AN ISO 9001:2015 CERTIFIED COMPANY

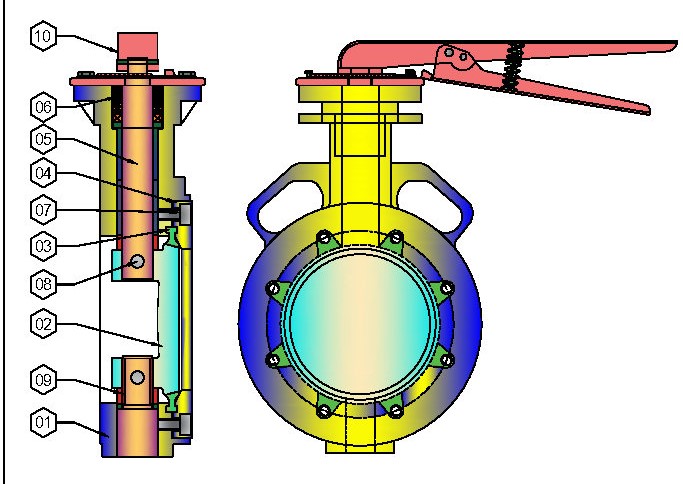

OFFSET SPHERICAL BUTTERFLY VALVE

OFFSET DISC DESIGN

We, “JOGANI” are a leading manufacturer and Exporters of OFFSET BUTTERFLY VALVE. Offset Butterfly valves means that the stem does not pass through the center line of the disc, but instead behind it, opposite of flow direction. When the stem is located right behind the center line of the disc, the valve is called single-offset. This design was developed to reduce the disc contact with the seal before full closure of the valve with the aim of improving service life of the valve. Today, single-offset valves have given way to double offset and triple offset butterfly valves.

In a Double-Offset Butterfly Valve, the stem is located behind the disc with an additional offset to one side. This double eccentricity of the stem enables the rotating disc to rub over the seat for only about one to three degrees.

In a Triple Offset Butterfly Valve is often used in critical applications and is designed similar to a double offset butterfly valve. A triple offset butterfly valve is more efficient and allows for less wear. Triple offset valves are often made of metal seats to create a bubble-tight shut-off. The metal seats allow butterfly valves to be used in higher temperature ranges.

High performance butterfly valve designs use the pressure in the pipeline to increase the interference between the seat and the disc edge. These butterfly valves have higher pressure ratings and are prone to less wear.

"JOGANI" OFFSET BUTTERFLY VALVE design is developed with following and using international Standard for Having an International Competency with Global Manufacturers.

We "JOGANI" follow an international standards and designs to get 100% superior quality with workmanship & service to maintain trust of our Clients and repeat order.

TECHNICAL DETAIL

DESIGN TYPE

OFFSET DESIGN

DOUBLE OFFSET DESIGN

TRIPLE OFFSET DESIGN

MFG. STANDARD

BS 5155, API 609 & AWWA 504

TESTING STANDARD

API 598/ BS 6755 Part-I

FACE TO FACE STANDARD

BS 5155, API 609 & AWWA 504 / ANSI B 16.10

PRESSURE & TEMPERATURE RATING

ASME B 16.34

PRESSURE CLASS

150#, 300#

PN10, PN 16

VALVE SIZE

1½” To 40”

(40 mm TO 1000 mm)

END CONNECTIONS

WAFER TYPE

FLANGE DRILLING

150#, 300#

PN10, PN 16

BS 10 TABLE D / E / F / H

VALVE SEAT LEAKAGE

CLASS VI (Zero Leakage)

MATERIAL OF CONSTRUCTIONS

CI TO IS 210 GR. FG 200

ASTM A 216 GR. WCB

ASTM A 351 GR. CF8 / CF8M / CF3 / CF3M

**Also Other Special Alloy available on request.

OPERATIONS

HAND WHEEL / GEAR

PNEUMATIC / ELECTRICAL ACTUATOR

**Also Other Special Operation available on request.

"Jogani Valve & Controls" is a technology driven engineering company, with strong presence in manufacturing of industrial valves.

© 2022 Jogani Valve & Controls - All Rights Reserved